Government Authority Solutions

Between budgetary constraints, EU regulations and constantly shifting public opinion government authorities are under immense pressure to reform their waste management strategies and at New AD we have been working with a number of government authorities to present a solution that is not only cost effective but also environmentally responsible.

Anaerobic digestion (AD) is not a new process; it is well established in the waste water industry and more recently it has been used for the treatment of biodegradable municipal waste (BMW). The process works by bacteria, which thrive in the absence of oxygen, breaking down the bio-degradable fraction of the waste to produce a stable residue. A number of outputs are produced once the organic material has been through the anaerobic digestion process, as illustrated in the figure below. All of the outputs can be affected by the quality of the feedstock which is put into the AD digester. This is why AD may be used alongside other treatment methods, such as after a material sorting facility (MRF).

The MRF could be used to remove the non-organic fraction of the waste (e.g. plastics) as a digester would not be able to process these. This stage often includes the use of a shredder to uniform the size of the material (12mm required for Animal By-Product Regulations) going into the digester this can help aid the digestion of the waste. When sorting technologies, such as MRFs and biological technologies like AD and composting are combined in this manner, the systems are termed mechanical biological treatment (MBT).

MBT is a process that could help governments to meet their obligations under the local landfill directives, of diverting biodegradable municipal solid waste from landfill to help protect the environment and reduce the amount of greenhouse gas emitted from landfill sites. MBT describes a number of different processes dealing with the biological treatment of waste. It is the combination of both biological and physical processes, which can be arranged in a number of different ways. MBT is an established waste treatment technology in many European countries such as Germany and Austria.

MBT Process

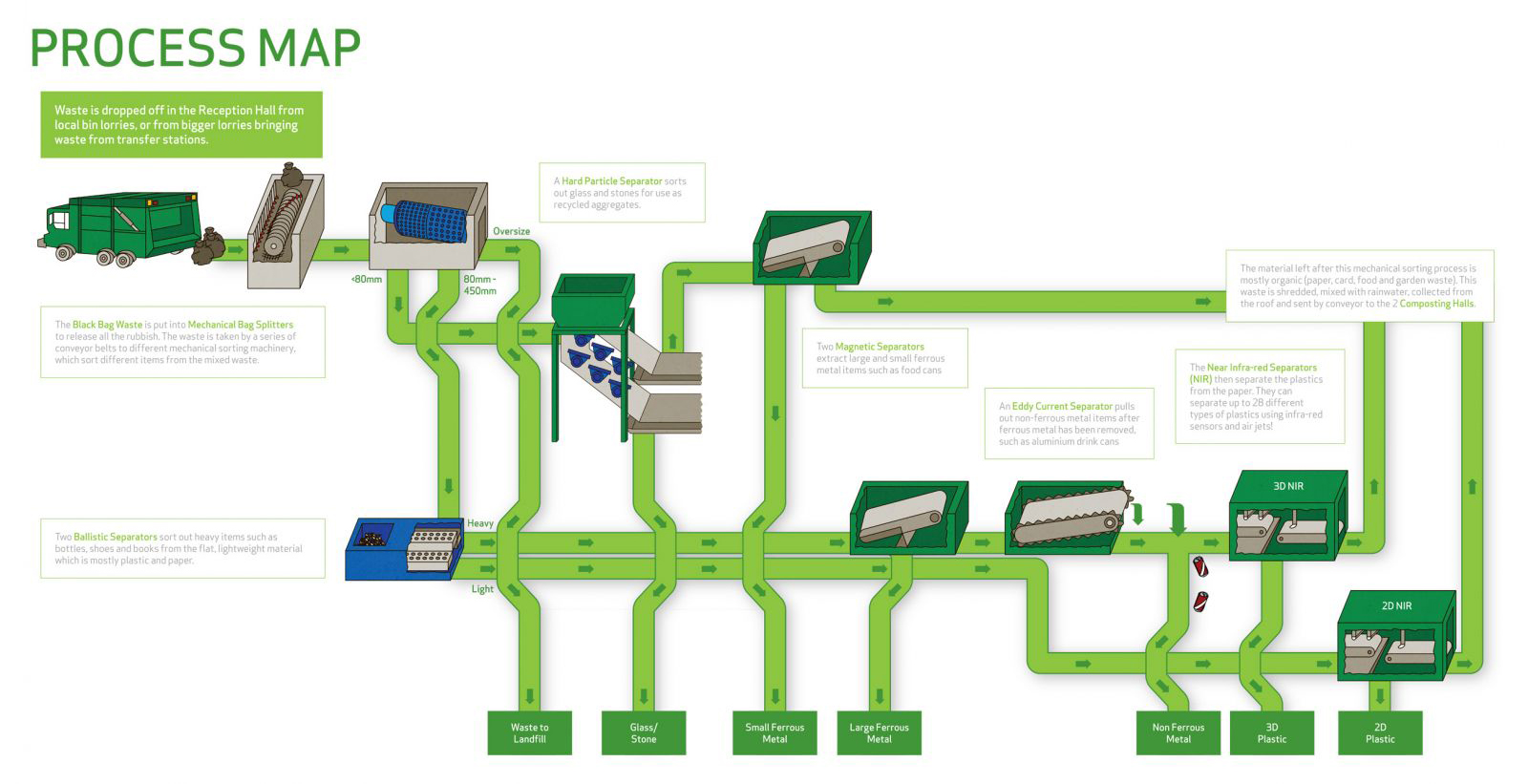

MBT is commonly used to treat municipal solid waste (MSW), it is capable of dealing with both mixed waste and source separated waste.The mechanical part which is the physical stage of an MBT process is normally at the front end of the process although it can also play a key role at the back end of the process. The MBT plant can be designed to have further mechanical screening at the end of the process to take out further contaminants and or reduce particle size, especially if the residues are going to be used for a purpose other than landfill Mechanical separation process can include size reduction/shredding of the waste, separation of ferrous and non-ferrous metals, heat/steam treatment and screening and/or size reduction of outputs.

Not all of the above are used in each MBT facility. For example if the aim is to maximise recovery and recycling and to stabilise the residue further that will be sent to landfill, a mechanical process which recovers dry recyclables (card, plastics, paper and metals) would be ideal. The mechanical process can be both a dry and wet process depending on the role of the final product. The aim of the mechanical process is that the remaining waste, after the mechanical separation, is the organic-rich fraction or biodegradable fraction which will be ideal for biological treatment.

The biological processes of MBT include aerobic decomposition to anaerobic digestion (AD), or a combination of the two. If AD is used to digest the organic-rich waste fraction biogas is often produced which can then be used as a source of energy. MBT is also often used to produce a soil conditioner and/or refuse derived fuel (RDF). The amount and quality of biogas, soil conditioner and RDF produced depends on the particular facilities composition (Juniper). Anaerobic or aerobic composting of mixed MSW will not produce a material of appropriate quality without some form of mechanical treatment at the front end of the MBT plant.

The MBT process is quite complex with a number of variables giving considerable flexibility. MBT systems can be a modular design which means they can be switched from processing mixed MSW to processing source separated organic waste, which may need to occur if the collection system is changed from a mixed waste collection system to a source segregated collection. Sites processing both mixed/residual MSW and to an increasing extent separately collected biowaste are often known as “double duty” sites, these sites, are quite diffused across Europe, and may provide a flexible answer to the need to tackle changes in schemes and of local strategy.

Output

The typical outputs which are produced from the AD process as shown above:

Gases; including methane, carbon dioxide and other trace gases which make up biogas. The biogas can be collected and cleaned and then used as a renewable energy source. The biogas which is produced can be used for heat and power which can then be used to run the plant and/or it can be sold to the national grid.

Due to the electricity produced from the AD process being a renewable energy source, biogas qualifies under the Renewable Obligations Certificates (ROCs) and the Feed-in-Tarriffs (FITs) scheme, see links below for more information;

Ofgem Information on ROCs

Renewables Obligation (ROCs)

Feed-in-Tarriffs

The amount of gas that is able to be converted to biogas is also affected by the type of plant used, HRT and again the feedstock. For example, dry AD plants normally produce less biogas than wet AD plants. The amount of methane in the biogas produced in waste digestion facilities can also vary between 30% and 75%.

Exemption

Most waste management activities are regulated by the Waste Management Licensing Regulations 1994 (as amended); however some activities can be registered as exempt. For an activity to be considered exempt the waste must be recovered without harm to human health and without using process or methods which could harm the environment. One possible use of the organic products produced by MBT is to apply it to land and this could be covered by a U1/U11 exemption, in England and Wales (For detailed information see www.environment-agency.gov.uk/business/topics/permitting/32322.aspx).

U11 allows the spreading of wastes to land where it results in benefit to agriculture or ecological improvement. There are certain restrictions in using exemption 9A, for instance you can not use exemption 9A if spreading compost like outputs (CLO) for agricultural benefit when you intend to grow biomass, due to the definition of agriculture currently used by the Environment Agency (The Agriculture Act, 1947). Paragraph 9A exemption is currently being reviewed by Defra. The Environment Agency must be notified if a paragraph 9A exemption is used. For more information please see www.environment-agency.gov.uk/subjects/waste/1416460/

Legislation

All MBT plants in the UK require permits/licences and are subjected to the usual rigorous monitoring by regulators. Waste facilities including digesters fall under a number of regulations, this can depend on the facility being operated and may include Waste Regulations, the Integrated Pollution and Control Directive (IPPC), the Industrial Emissions Directive (IED) and the ABPR if the plant is accepting food waste.

Any MBT facility must follow the Intergrated Pollution and Control Directive (IPPC) which was implemented to minimise the pollution from various industrial sources to the environment. If an MBT facility is accepting food waste and one of its outputs is compost like outputs (CLO) which is to be applied to land then the facility must comply with the Animal By-Products Regulations. For more information see: www.gov.uk/government/policies/protecting-animal-health-and-preventing-disease-including-in-trade/supporting-pages/animal-by-products